When it comes to high-demand, precision-driven industries, few operate under the time-sensitive pressure and quality expectations of seafood processing.

For De Costi Seafoods—Australia’s most recognised fresh seafood brand—there is simply no room for downtime.

And at the heart of their state-of-the-art operation is a piece of machinery that’s been quietly (but powerfully) doing the heavy lifting: the Pilot Air DCR135VS rotary screw air compressor.

A Legacy of quality and reliability

Founded in 1981 at the iconic Sydney Fish Markets in Pyrmont, De Costi Seafoods has grown into a national powerhouse in the retail and wholesale seafood markets. The company sources premium quality seafood from across Australia, New Zealand, and the Asia Pacific, supplying restaurants, hotels, and cafes with unmatched freshness and consistency.

To keep up with the volume and demands of its growing customer base, De Costi operates two major processing facilities. Their flagship site, New South Wales, is enormous. It includes three dedicated production areas, a freezer capacity of 1,800 pallets, and various cold storage, packing, and dry goods zones—all of which rely heavily on compressed air to operate efficiently.

For over a decade, De Costi has trusted Pilot Air to deliver that critical compressed air, and this partnership has paid off tenfold.

“Over 100,000 hours of operation — proven performance in Australia’s toughest conditions.”

The 100,000-Hour workhorse

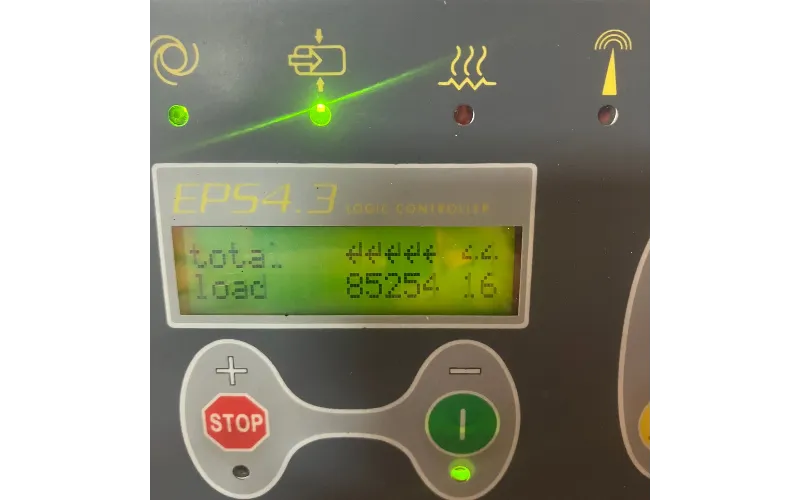

Among the several air compressors supporting De Costi’s daily operations, one machine stands out: the Pilot Air DCR135VS rotary screw compressor. Recently, this powerhouse unit hit an extraordinary milestone—over 100,000 hours of operation. That’s the industrial equivalent of a car travelling more than 4.8 million kilometres.

Operating 15 hours a day, six days a week, this compressor is integral to the facility’s workflow, powering everything from pneumatic tools to automated processing equipment.

Luckie Koliandris, Head of Maintenance at De Costi’s Auburn site, puts it simply:

“The compressor is a beauty. Incredibly reliable, bulletproof, and high-performance.”

Zero room for downtime

There is no margin for error in an environment where freshness is king. Any interruption in air supply halts production—and when you’re dealing with perishable seafood, time is everything.

“The air compressor is one of the most vital pieces of infrastructure in the processing warehouse and runs most of our machines and tools,” says Koliandris. “Without it, processing and production come to a standstill. Fresh seafood requires immediate and precise processing capability to ensure we continue to supply our customers with the freshest and highest quality seafood. Without the reliability of the air compressor, our service is compromised—and we never compromise.”

Key Takeaways

Proven Reliability

De Costi Seafoods’ rotary screw compressor has run for more than 100,000 hours, proving long-term durability in demanding processing conditions.

Industrial Applications –

Pilot Air systems support continuous, large-scale operations like seafood processing, cold storage, and automated packaging.

Australian Tough Design

Built to handle long duty cycles, heat, humidity, and dust, Pilot Air compressors are engineered specifically for local conditions.

Service & Support

With service and maintenance and a strong spare parts network, Pilot Air ensures minimal downtime for critical operations.

Service that matches the product

It’s not just the compressor’s performance that keeps De Costi loyal—it’s the ongoing support and expertise of the Pilot Air NSW service team. The team that installed the DCR135VS regularly serviced it, ensuring peak performance and longevity.

“The Pilot Air team is fantastic to work with; nothing is ever too big or too small. They have always looked after our interests, and we will continue to employ Pilot Air air compressors now and into the future,” Koliandris adds.

“Trusted by Sydney’s leading seafood processor and industries nationwide.”

Why does the compressor work so well?

The range of Pilot Air rotary screw air compressors aren’t just machines—they are a long-term solution engineered for demanding industrial environments. Featuring variable speed drive technology, it ensures energy efficiency while maintaining consistent output, even under fluctuating demands. The Pilot Air rotary screw air compressor is built to run—and keep running.

Key features include:

- Heavy-duty rotary screw design

- Intelligent control systems for performance monitoring

- Exceptional energy efficiency

- Minimal maintenance requirements

A benchmark in industrial air power

In the high-stakes world of seafood processing, De Costi Seafoods cannot afford to compromise on reliability, performance, or service—and with Pilot Air compressors, they don’t have to.

The DCR135VS’s milestone of 100,000+ hours of reliable service is more than just a number—it’s proof of engineering excellence and a partnership built on trust. For any industrial business seeking a reliable air compressor solution, Pilot Air is the brand that delivers.

Experience the best in rotary screw air compressors

Pilot Air has an extensive distribution network along with a dedicated onshore service and maintenance team and in-house technical specialists to engineer and customise the ideal compressed air solution for your business. When you demand the highest performance from your team and your equipment Pilot Air is your compressed air partner. Contact us today and experience the Pilot Air difference.