The term “smart tech, smart buildings, etc.” has been used in corporate lingo for some time. Every piece of infrastructure or facility integration needs to meet the smart criteria to be considered.

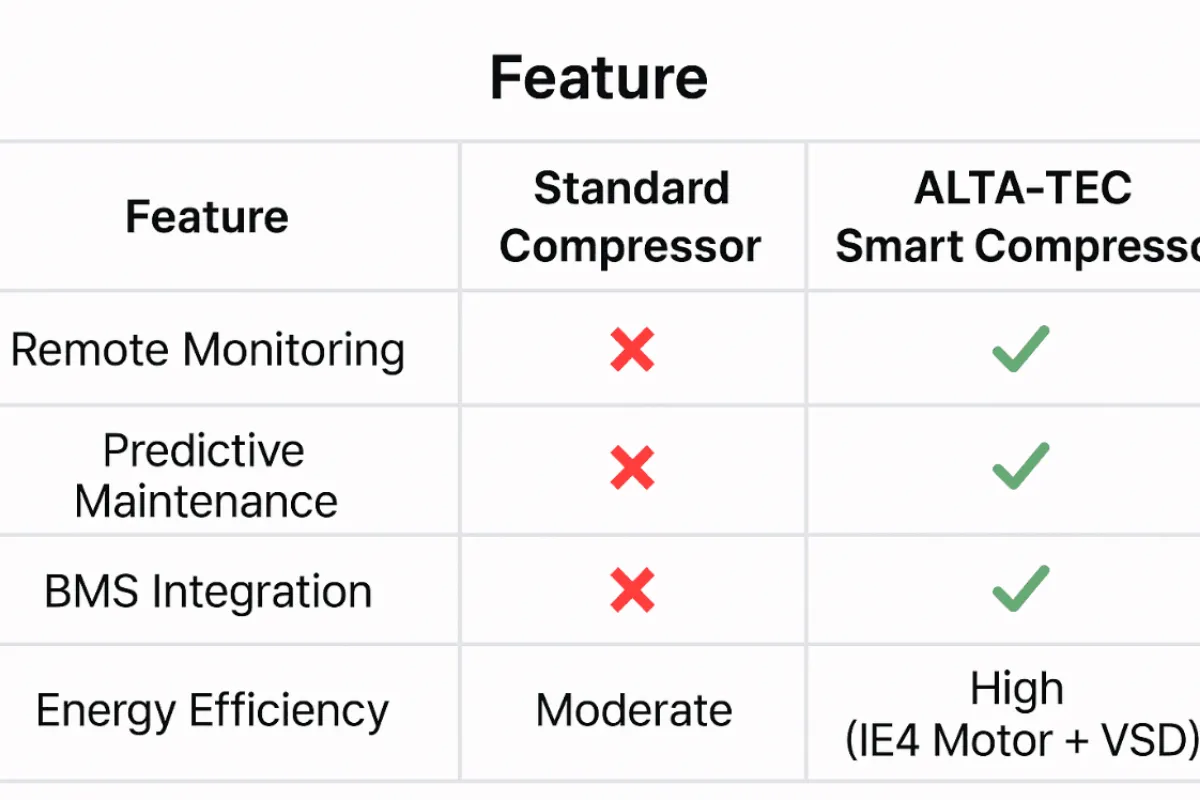

This demand has transformed the design and manufacturing of industrial air compressors, resulting in highly efficient, digitally integrated systems that significantly reduce energy consumption and CO2 emissions. These systems offer remote monitoring capabilities, preventative maintenance, and performance analysis.

They are no longer a static set and forget until something goes wrong liability. Now, they are an essential part of strategic operational decision-making.

“Smarter air, lower costs — IoT-connected compressors built to perform in Australia’s toughest conditions.”

Why rotary screw compressors lead the way

At Pilot Air, we describe ourselves as category purists. We only design and build air compressors for the Australian industry. While other brands scramble to keep pace, furiously allocating resources across a broad range of product development, our R&D goes solely into air compressors.

We know that rotary screw compressors are the best option to meet the evolving demands of smart operations, and our sole focus gives us a distinct advantage. While our competitors work reactively, we’ve been designing and innovating leading rotary screw air compressor models that meet Australian standards and exceed the demands of smart industrial compressed air infrastructure for the best part of fifty years for the Australian industrial sector, including healthcare, mining, and food production.

Industry experts know that rotary screw air compressors offer consistent output, less maintenance, and superior scalability options. This is a driving force behind Pilot Air’s ALTA-TEC family of rotary screw air compressors. The ALTA-TEC range is engineered for performance and the future.

At its core is the Two-Stage Rotary Screw design partnered with a Permanent Magnet IE4 Super Premium Efficiency Motor. This smart innovation is the best technology to reduce energy consumption without compromising performance.

It is not just the mechanics that make our ALTA-TEC rotary screw air compressors the smart choice. These units feature advanced Login electronic controllers, which enable remote management and real-time load adjustment. Fully supported by our onshore servicing and maintenance scheduling, audited design installation, business and facility managers and owners can accurately forecast substantial life cycle savings and still expect leading reliability, performance, and a level of customer service that can’t be matched.

Key Takeaways

Real-time Monitoring

IoT-enabled compressors track performance live, sending alerts before issues arise.

Energy Efficiency Gains

Smart controls and variable speed technology reduce waste and cut electricity costs.

Built for Harsh Conditions

Designed for heat, humidity, dust, and coastal environments unique to Australia.

Future-ready Integration

Seamlessly connects with facility BMS and digital infrastructure to support Industry 4.0 operations.

What to look for when planning a compressed air upgrade or installation

When your business needs to upgrade its compressed air system or you have a new facility, there are four primary considerations to consider.

Firstly, air compressor downtime is costly. Look for a system that offers predictive maintenance. The Pilot Air ALTA-TEC range of rotary screw air compressors has built-in diagnostics that intervene before a fault occurs. This innovation mitigates outages and extends the compressor’s life.

Next is BMS, building management systems. The ALTA-TEC range is connected and can “talk” to your other infrastructure, whether that means adjusting output or integrating with renewable energy sources. The systems are highly adaptable and meet the expectations of modern facilities.

ESG and carbon reporting are big-ticket considerations. The ALTA-TEC rotary screw air compressors are built to reduce energy consumption and minimise carbon emissions.

Local knowledge and onshore support cannot be underestimated. As we mentioned, Pilot Air is a category purist, and we only build and supply world-leading air compressors. We’ve been working closely with the industrial sector for over fifty years. We know local conditions and the local demands. Our service and support team is onshore, and dedicated account managers are empowered to work autonomously and make decisions. We know the Australian regulatory standards, we can respond quickly, and when you call our office, you speak to decision-makers without the runaround.

Whether you’re designing a new facility or retrofitting an existing one, Pilot Air has the expertise, experience, and range of rotary screw air compressor solutions for today’s needs and tomorrow’s opportunities.

“Trusted by Sydney businesses, Pilot Air’s smart technology delivers efficiency, reliability, and peace of mind.”

Experience the best in rotary screw air compressors

Pilot Air is one of Australia’s leading suppliers of rotary screw air compressors. Our team is qualified to conduct a diagnostic assessment and install the most suitable compressed air infrastructure with built-in scalability for your immediate needs. Pilot Air is proudly Australian-owned and independent, with onshore maintenance and service, skilled technicians, and a large inventory of spare parts. Contact our team today.